|

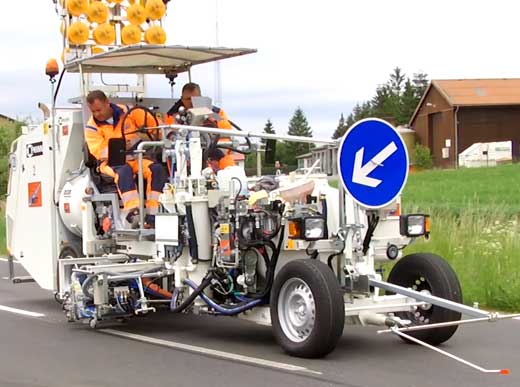

TrucksExamples for an individually built and configured road marking truck Figure: Example out of our truck product line Available Application techniques

|

|

DescriptionWe gladly develop customised road marking trucks matching national, climatic and technical requirements. The following shows some samples from our large range of individually developped road marking trucks. |

||

SpecificationsEngine: Air output: Pressurised glass bead containers: |

||

|

Road Marking Machines for All Areas of UseBest quality, innovative technologies and reliable all-round serviceHOFMANN marking machines have convinced users with their quality seal "Made in Germany" and comprehensive, competent advice in more than 160 countries around the world since 1952. We are proud to offer solutions to meet any requirements and needs. Contact us. We will gladly help you out! |

|

Filter Available Application techniques |

||

|

H33-4Most compact machine with very high capacities and excellent hill climbing ability Figure: example machine out of H33-4 product line Available Application techniques

|

|

DescriptionRobust, high-effective 7-ton construction machine axle with hydraulically switchable speed ranges combined with a high-speed hydraulic motor. Cooling system with automatic adaption of ventilator speed to ambient temperature and machine load (noise reduction at normal machine load and higher cooling performance at extreme machine load). Inlet of whole cooling air from upper side of the machine - far away from spray mist. Two pressurised glass bead containers. Filling openings for glass beads at the side of the machine in ideal filling height. Cockpit incl. all necessary operational controls laterally adjustable without the need to install guides. Arrangement of operating and supervising instruments can be easily modified according to individual requirements. Adjustable, easy extractable spray gun support for centre and edge line markings. Motor compartment easily accessible for service work. High ground clearance also eases service works from below. Excellent panoramic view, also when driving backwards. Available as an option: Line widths: |

||

Specifications4-cylinder 3 800 cm³, Version I: ** Version II: ** ** further exhaust stages upon request

2 600 up to 3 500 l/min at 7,5 bar; Compressed air cooler |

||

|

H26-4A compact machine with high capacities Figure: example machine out of H26-4 product line Available Application techniques

|

|||||||||||

DescriptionRobust, high-effective 7-ton construction machine axle with hydraulically switchable speed ranges combined with a high-speed hydraulic motor Cooling system with automatic adaption of ventilator speed to ambient temperature and machine load (noise reduction at normal machine load and higher cooling performance at extreme machine load) Inlet of whole cooling air from upper side of the machine - far away from spray mist Two pressurised glass bead containers. Filling openings for glass beads at the side of the machine in ideal filling height Cockpit incl. all necessary operational controls laterally adjustable without the need to install guides Arrangement of operating and supervising instruments can be easily modified according to individual requirements. Adjustable, easy extractable spray gun support for centre and edge line markings Motor compartment easily accessible for service work.High ground clearance also eases service works from below Excellent panoramic view, also when driving backwards Available as an option: Line widths: |

||||||||||||

Specifications4-cylinder 3 800 cm³, Version I: ** 74,0 kW at 2 600 rpm Version II: ** 55,4 kW at 2200 rpm 2 400 l/min at 7,5 bar; Pressurised glass bead containers: Dimensions (L x W x H mm): Weight, equipped: Container volumes:

|

||||||||||||

|

H18-2A compact, narrow and maneuverable machine with medium-sized capacities Figure: example machine out of H18 product line Available Application techniques

|

|||||||||||

DescriptionHydraulic drive with wheel motor with infinitely variable speed adjustment Hydraulic multi-disk parking brake Cooling system with automatic adaption of ventilator speed to ambient temperature and machine load (noise reduction at normal machine load and higher cooling performance at extreme machine load) Inlet of whole cooling air from upper side of the machine - far away from spray mist Exhaust pipe is under the machine and outlet is adjustable depending on the application One pressurised glass bead container Cockpit with all operating elements adjustable without the need to install guides High visibility during center- and edge line markings Fold-out ladder on the seat support Individual application units (exchangeable container) or exchange of front chassis incl. application unit at low effort by quick opening device systems and modular design principle Engine compartment easily accessible for service work Excellent panoramic view, also when driving backwards Line widths:

|

||||||||||||

Specifications4 cylinder 2400 cm³ Version I: ** Air output, alternatively: Pressurised glass bead container: Dimensions (L x W x H mm):

Container volumes:

|

||||||||||||

|

RM3D-2A very narrow and extremely manoeuvrable machine Figure: example machine out of RM3D-2 product line Available Application techniques

|

|||||||||||

DescriptionHydraulic drive with wheel motor with infinitely variable speed adjustment Hydraulic multi-disk parking brake Cooling system with automatic adaption of ventilator speed to ambient temperature and machine load (noise reduction at normal machine load and higher cooling performance at extreme machine load) Inlet of whole cooling air from upper side of the machine - far away from spray mist Exhaust pipe is under the machine and outlet is adjustable depending on the application One pressurised glass bead container Cockpit with all operating elements adjustable without the need to install guides High visibility during center- and edge line markings Fold-out ladder on the seat support Individual application units (exchangeable container) or exchange of front chassis incl. application unit at low effort by quick opening device systems and modular design principle Engine compartment easily accessible for service work Excellent panoramic view, also when driving backwards Line widths:

|

||||||||||||

Specifications4-cylinder 1500 cm³, 33,0 kW at 3000 rpm Air output: Pressurised bead container: Dimensions (L x W x H mm): Weight, equipped: Container volumes:

|

||||||||||||

|

H16-3A narrow, manoeuverable machine with small capacities Figure: example machine out of H16-3 product line Available Application techniques

|

|||||||||||

DescriptionHydraulic drive with wheel motor with infinitely variable speed adjustment Hydraulic multi-disk parking brake Large axle base and front wheel steering system with zero backlash for best roadability and excellent handling, especially wherever the marking results depend on high manoeuvrability Application units favourably mounted in the back of the machine Low position of driver’s seat as well as platform; comfortable get on / off Engine compartment easily accessible for service work Line widths:

|

||||||||||||

SpecificationsVersion I**): Air output: Glass bead container: Dimensions (L x W x H mm): Container volumes:

|

||||||||||||

CONTACT US

+13901808120 tygerzhang@msn.comGET IN TOUCH